Workshop

Our 24/7 service workshop has more than 40 years of experience within subcontractor work – everything from plate bending to special welding on a welding robot with customized solutions.

The workshop is equipped with the market’s latest machines and technology, which ensures the best quality and shortest delivery time. In addition, our workshop has obtained DNV-GL welding certification, which is your guarantee for top production facilities and work procedures that meet the most demanding safety standards.

Our workshop offer:

- Own engineering department

- CNC controlled machines

- Total supplier with a wide machine package

- 100% traceability = Delivers / produces only materials with the right certificates

- And much more…

For more information, please contact:

Sheet Metal Workshop

Our Sheet Metal workshop offer all types of traditional and classic sheet metal fabrication.

We have extensive experience in solving all kinds of different jobs from day-to-day jobs to larger and more complex tasks.

Laser

With our Amada fiber laser, we can handle all jobs in plate sizes up to 4.050 mm X 2.050 mm.

Roller

Our roller can handle plate thicknesses up to 11 mm with a width of 2.550 mm.

Press brake

The press brake has a maximum bending length of 4.100 mm and a maximum tonnage of 4.000KN.

Capacity:

Black steel

Stinless steel

Aluminium

Brass

Copper

Titanium

25mm

15mm (20mm)

12mm

8mm

6mm

5mm

Blacksmith Workshop

Our Blacksmith workshop offers a wide range of different welding task. The Blacksmith workshop is highly specialized in MIG/MAG and TIG welding, which can be used for steel, stainless steel and aluminium.

The Blacksmith workshop offers:

- MIG/MAG and TIG welding

- Synchronous welding on tanks

- SMO and Duplex welding

Welding machines

The workshop is equipped with the latest Migatronic welding machines.

Plasma welding

Our Migatronic Longstock Welder has a maximum length of 2.600 mm.

Machine Workshop

Our Machine workshop is ready to receive your job. We can adapt to any task, small or large, and we ensure you the shortest delivery time without compromising the quality.

We are used to handle many different types of jobs, and have great experience with both single piece production as well as series production.

The machine package consists of:

| Z (height) | Y (width) | X (length) | Load | |

|---|---|---|---|---|

| Vertical machining center Kiheung U 1000 Haas vf-6-50 |

1.200 mm 762 mm |

1.200 mm 813 mm |

3.500 mm 1.626 mm |

15 tons |

| Horizontal machining center Tos WHN 13 CNC |

1.500 mm | 2.500 mm | 3.000 mm | 12 tons |

| Maximum machining diameter | Maximum machining length | |

|---|---|---|

| 5-akse Mazak lathe Mazak Integrex 400-IV S |

760 mm | 1.067 mm |

| Lathe – CNC Geminis scnc 1000 dc |

1.000 mm | 2.000 mm |

| Pin height: | Pin distance | Swing over beam | Swing over sled | |

|---|---|---|---|---|

| Pinacho Smart-turn 6/310 | 310 mm | 2.000 mm | 620 mm | 400 mm |

| Cutting | Max cutting width |

|---|---|

| Cosen – C-560NC | 560 mm |

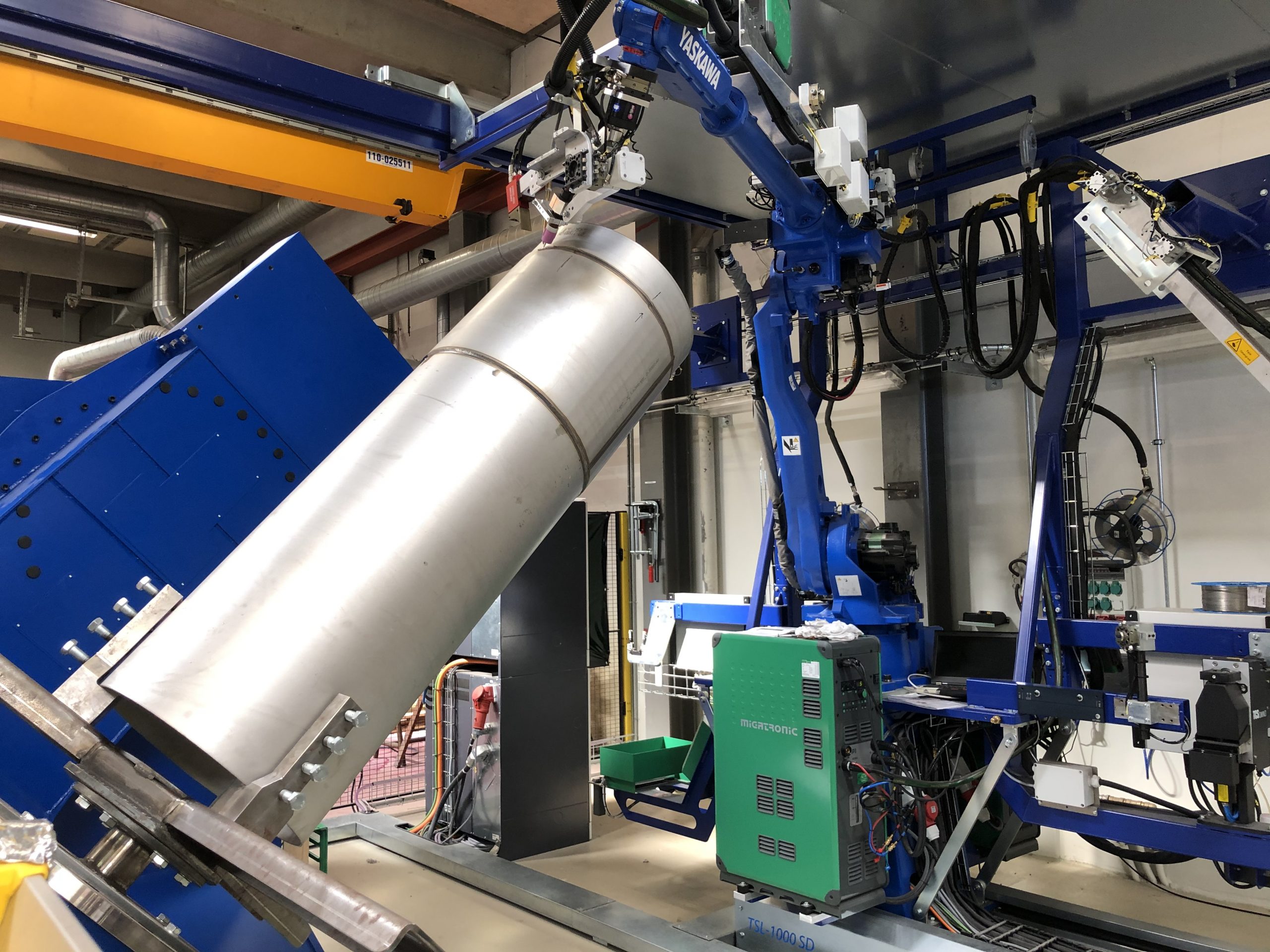

Welding Robot

The welding robot ensures you the most even welds in a series of production. By using a welding robot, the production time is reduced without compromising on the quality and durability in any way.

The welding robot ensures you the most even welds in a series of production. By using a welding robot, the production time is reduced without compromising on the quality and durability in any way.

Welding robot

Our Yaskawa MH50-20II welding robot is with DX 200 control. The welding robot is fitted with automatic switch between MIG / MAG and TIG welding. It is equipped with 2 different workstations:

Station 1:

Yaskawa turning station, axle controlled type HTC 1000D

Fixture dimension max. L 3.000 mm / W 1.250 mm

Load max. 1.000 kg

Station 2:

Yaskawa L-manipulator type MT1 3000S2D

Max. workpiece radius 1.800 mm

Load max 3.000 kg

For more information, please contact: