Why choose a SOx scrubber system / Exhaust Gas Cleaning System (EGCS)

Since May 2005, comprehensive environmentally friendly IMO (International Maritime Organization) regulations have been in force. The IMO regulations have been progressively tightened over the years to reduce Sulphur Oxides emissions, known as SOx, from ships.

From January 1st, 2020 the limit for Sulphur in fuel oil used on board ships operating outside designated emission control areas (ECA) has been reduced to 0.50% m/m (mass by mass).

If the vessel operates in areas where SOx emissions are controlled, compliance can be achieved using low Sulphur fuel, or by cleaning exhaust gases using SOx scrubbersIn order to meet the SOx emission regulations, the shipowners have 3 choices;

- Install a SOx scrubber system (described in detail below)

- Switch from high Sulphur fuel to low Sulphur fuel

- Switch to natural gas (LNG)

What is a SOx scrubber System / Exhaust Gas Cleaning System (EGCS)?

The technical term of a SOx scrubber system is “Exhaust Gas Cleaning System (EGCS)” but are commonly known as “scrubbers”. In a scrubber, the Sulphur oxides in the exhaust are passed through a water stream reacting with it to form sulphuric acid and are removed from the exhaust gas which then passes out of the system.

Sulphuric acid is highly corrosive, but when diluted with sufficient alkaline seawater it is neutralized and the wash water can be discharged into the open sea (Open Loop system) or after being treated in a separator to remove any sludge (Closed Loop scrubber system or Hybrid scrubber system)

The scrubber tower/body is installed inside the ship’s funnel casing.

How is a SOx scrubber system design?

ME Production offer two different SOx scrubber system designs to meet the demands and requirements of our customers. They fit all types of vessels, sizes and engines. The design or the scrubber type is called Inline (I-type) and U-type (U-turn) scrubber. Depending on the customer’s specific requirements, ME Production is able to customize their SOx scrubber system design, so it fits into any vessel.

Inline scrubber design (I-type)

Inline scrubber design (I-type)

The ME Production Inline scrubber system is designed for dry mode operation in combination with packed bed. The marine MEP Inline scrubber system also called I-type scrubber system is designed to provide operational flexibility and save space. The MEP exhaust gas Inline scrubber system overcome any space restrictions that can prove a challenge for the scrubber system operations, which means that our exhaust gas SOx scrubber design has a perfect fit where space is limited, and the project requires custom solutions.

The marine Inline exhaust gas scrubber system has a reduced footprint and no external venturi which results in an easier installation which consequently reduces the downtime of the vessel.

The marine Inline exhaust gas scrubber system has a very flexible range and fits all types and sizes of vessels in Open Loop, Closed Loop or Hybrid specification. The MEP exhaust cleaning system is shipped fully assembled with insulation and all components.

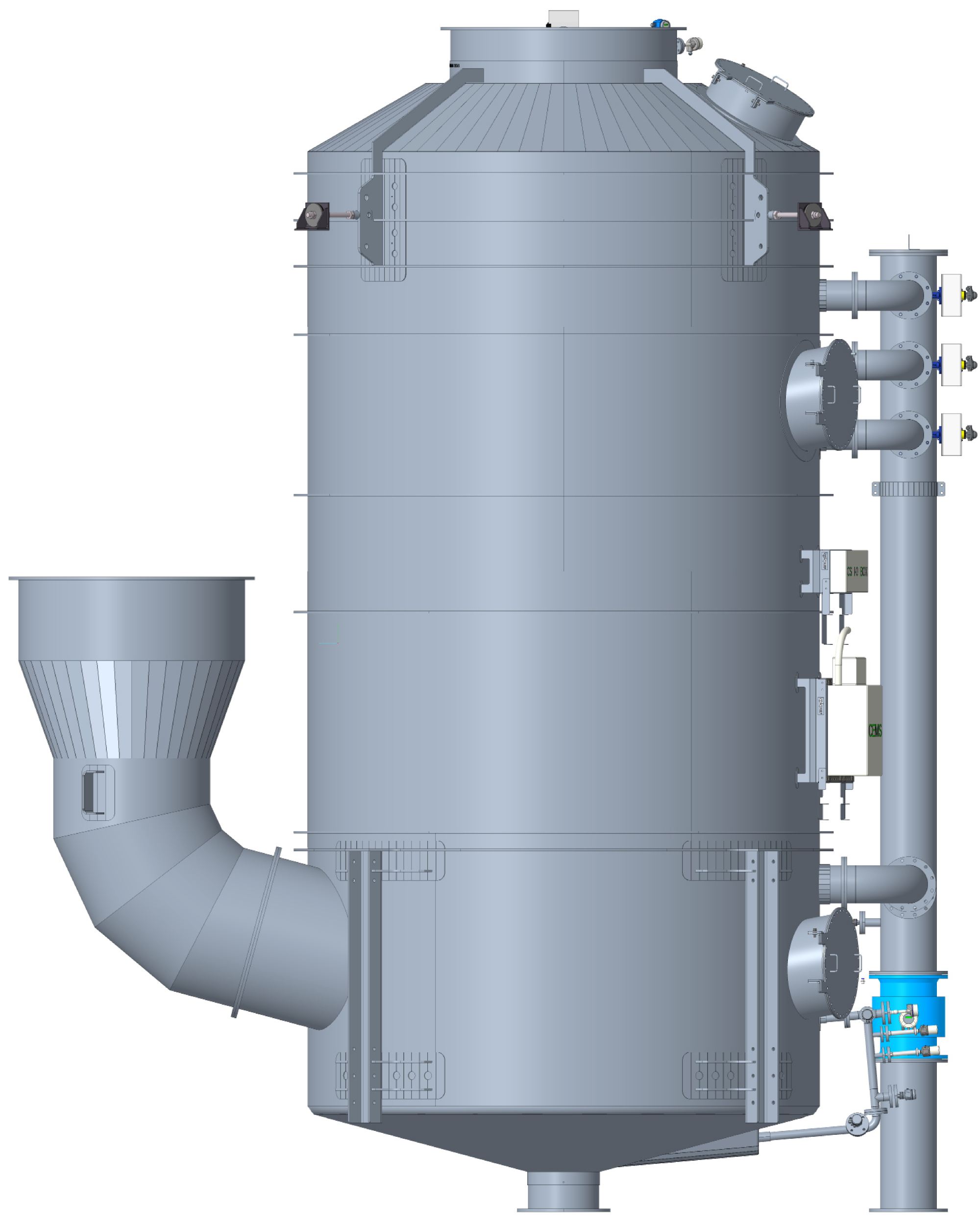

U-type scrubber design

U-type scrubber design

The MEP U-type exhaust gas scrubber system is the ideal design choice for new buildings or retrofits with adequate space in the funnel to fit an exhaust system with bypass line. Except for the space requirement, the U-type scrubbers exhaust gas cleaning system shares overall the same proven concept and qualities as the Inline scrubber system design with packed bed and ensures compliance and minimal wear.

It has the same very simple design as the inline scrubber and a minimal power consumption, pressure drop and general low maintenance requirement. The MEP U-type exhaust gas scrubber enables a lower installation height, placed in level of economizer or exhaust boiler

The U-type scrubber design has a very flexible range which fits all types and sizes of vessels in Open Loop, Closed Loop or Hybrid specification.

Both the U-type scrubber system and the Inline scrubber system can easily accommodate the combustion units of the individual vessel.

What is a SOx scrubber system mode?

In the shipping sector, wet scrubbers are divided into two types; Open Loop and Closed Loop which were developed separately, but which are now usually combined into a third type; a Hybrid scrubber system. The basic technology in all of the scrubber systems is the same. When exhaust gas enters the exhaust gas cleaning system, it is sprayed with sea water.

In the shipping sector, wet scrubbers are divided into two types; Open Loop and Closed Loop which were developed separately, but which are now usually combined into a third type; a Hybrid scrubber system. The basic technology in all of the scrubber systems is the same. When exhaust gas enters the exhaust gas cleaning system, it is sprayed with sea water.

The SOx react with water to form Sulphur acid. In an Open Loop scrubber system, the natural alkalinity of the seawater neutralizes the acid. In a Closed Loop scrubber system, caustic soda helps to do this.

The Hybrid scrubber system is a combination of both wet types that will operate as an Open Loop system where water conditions and discharge regulations allow and as a Closed Loop system at other times. Hybrid systems are proving to be the most popular because they can cope with every situation.

Open Loop scrubber mode

The Open Loop scrubber system uses seawater to neutralize the SOx of the exhaust gas. Open Loop scrubbers pump seawater into the scrubber and discharge the wash water back to the sea. Seawater is used as a washing medium to clean the exhaust gas.

This simple process exploits the natural alkalinity of seawater to absorb the SOx. The life of the sea will not be harmed by the used seawater when it is pumped back to the sea.

Closed Loop scrubber mode

A Closed Loop scrubber system works on similar principals to an Open Loop scrubber system, but instead of seawater it uses fresh water treated with a chemical (NaOH) as the scrubbing media. This converts the SOx from the exhaust gas stream into harmless sodium sulphate. The wash water from a Closed Loop scrubber passes into a process tank where it is cleaned before being recirculated.

The losses is made up with additional freshwater. A small quantity of the wash water is bled off to a treatment plant before discharge to sea. Cleaned effluents can be safely discharged overboard without harming the environment.

A small bleed-off is extracted from the closed loop and treated to fulfill IMO requirements.

If operation in zero discharge mode is requested, the residue can be led to a holding tank for scheduled and periodical discharging.

Hybrid scrubber mode

A Hybrid scrubber system is designed, as a mix between both Open Loop and Closed Loop scrubber systems. It provides the flexibility to operate in closed loop mode (including zero discharge mode) depending on the conditions (seawater alkalinity, discharge restrictions, etc.) and in Open Loop mode without consuming any alkaline agent.

This option provides high flexibility of operation in low alkaline waters as well as in the open ocean.

SOx scrubber installation

There are many ways to prepare a SOx scrubber system for installation at a yard. ME Production provides the option to have the marine scrubber unit insulated, assembled and wired. The remaining installation of the scrubber system at the yard is connecting inlet- and outlet piping, power supply and communication to IO box.

This solution provides two opportunities for shipowners – either to finish the installation during yard stay or leave wiring and pipe work to be carried out during operation in order to save time.

ME Production has achieved great results with 3-week complete yard installations for both Open loop scrubber systems, Closed Loop scrubber systems and Hybrid scrubber systems. The installation time of course depends on yard performance and specific demands for yard selection. The shipowner realizes fuel cost savings from day one after departure from yard with a fully functional scrubber system.

This concept provides certainty of system implementation and a definite deadline. If the shipowner prefers 6-12 months of installation on-board for piping and final installation, ME Production offer this as well.

SOx scrubber service and maintenance

To secure your day-to-day operation and minimize downtime for the shipowners it is recommendable to choose a SOx scrubber manufacturer with a scrubber service department. With ME Production great experience and knowledge in building scrubbers, we also offer our customers a beneficial scrubber service, support and maintenance agreement.

ME Production offer the full “scrubber service package” where you are guaranteed full support and service to secure your day-to-day operation.

Having a SOx scrubber service, support and maintenance agreement you reduce your operating costs by improving your uptime, secure you meet compliance and an on-demand troubleshooting your equipment.

As an extra service ME Production scrubber service department offer you a remote on-line real time PLC/system support. In addition, we want to support your maintenance programs and provide training to make sure your operators are up to date.